About LJ Fabricators

December 25, 2023

About LJ Fabricators

Est. 1983

Our Mission

Devoted to being the industry leader in laser cutting and custom metal fabrications, focused on circling our customers’ needs while exceeding their expectations in service and quality.

We will accomplish this through:

- Flexibility in planning

- Delivering to our customers’ expectations

- Ensuring a culture of committed team work

- Excellent communication throughout our organization

- Recognition of each team member as vital to the company’s success

- Christ Centered Leadership

LJ Fabricators History

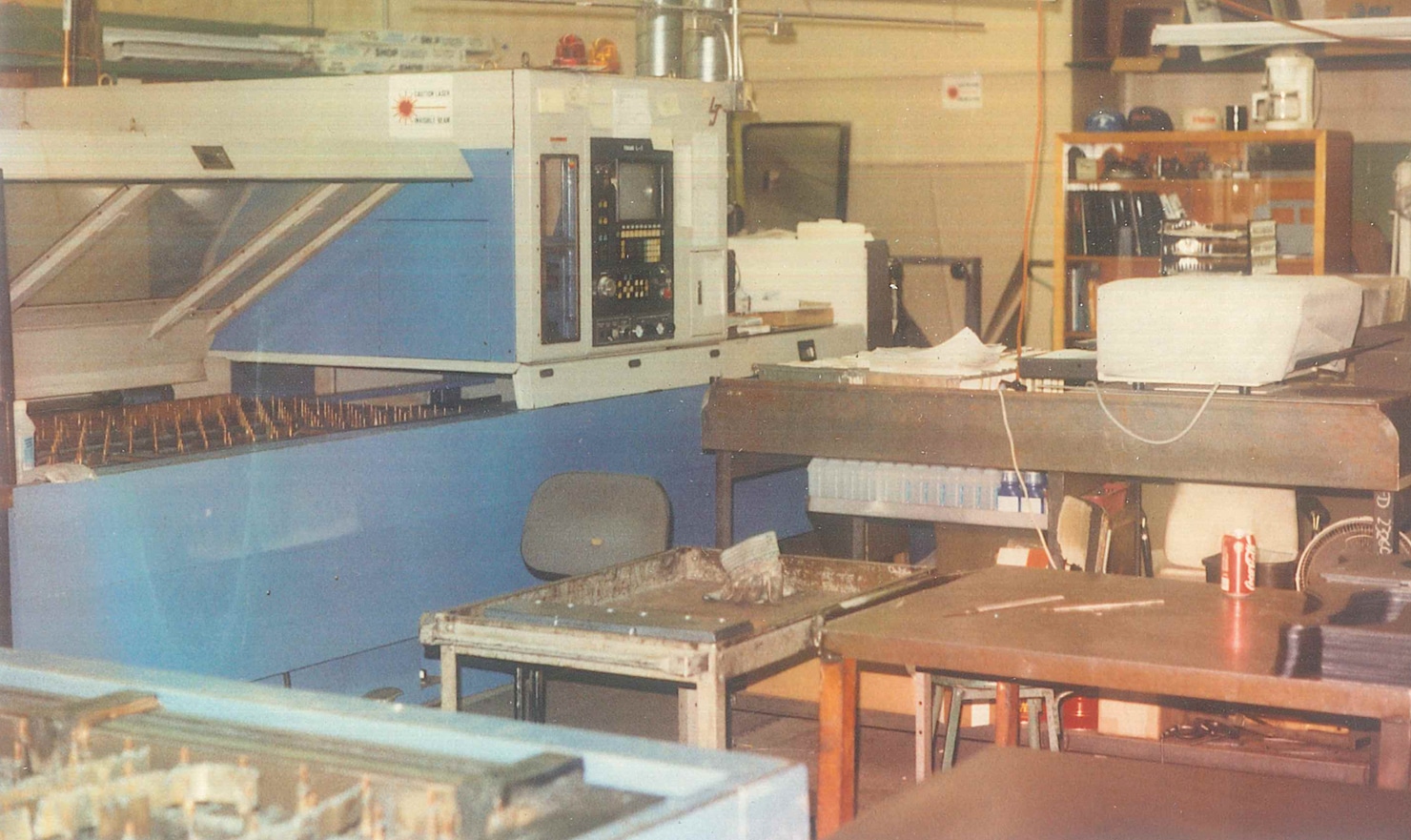

LJ Fabricators, Inc. was established in June of 1983 by Larry A. Johnson in a 6,000 sqft facility located in Rockford IL (Northwest of Chicago). Starting the business with one other employee, the company offered traditional metal fabricating job shop services. During the first decade, the company realized the need to increase capacity and expand the services provided, the metal solutions timeline includes:

Original facility expanded to 11,200 square feet and additional employees were hired

Purchased first 1.5kW Multi-axis CO2 Laser

Purchased 2kW CO2 Laser

Began construction on new 39,000 square foot facility, which is now the current location of LJ Fabricators next to the Chicago Rockford International Airport

175 ton press brake, 10′ long

2003 was a big year for LJ Fabricators. We achieved the ISO 9001 certification, expanded our facility to over 59,000 square feet and added a 10 ton overhead crane spanning 70′

170 kVA resistance welder and a 200 kVA resistance welder

Deburr & edge rounding machine

6kW fiber laser and a 44-ton press brake, 3 feet long

Added a 28 foot box delivery truck and another deburr & edge rounding machine

Hardware insertion machine and a 100 kVA resistance welder

10kW fiber laser

Hardware insertion machine and raw material storage towers

88-ton press brake, 5 feet long

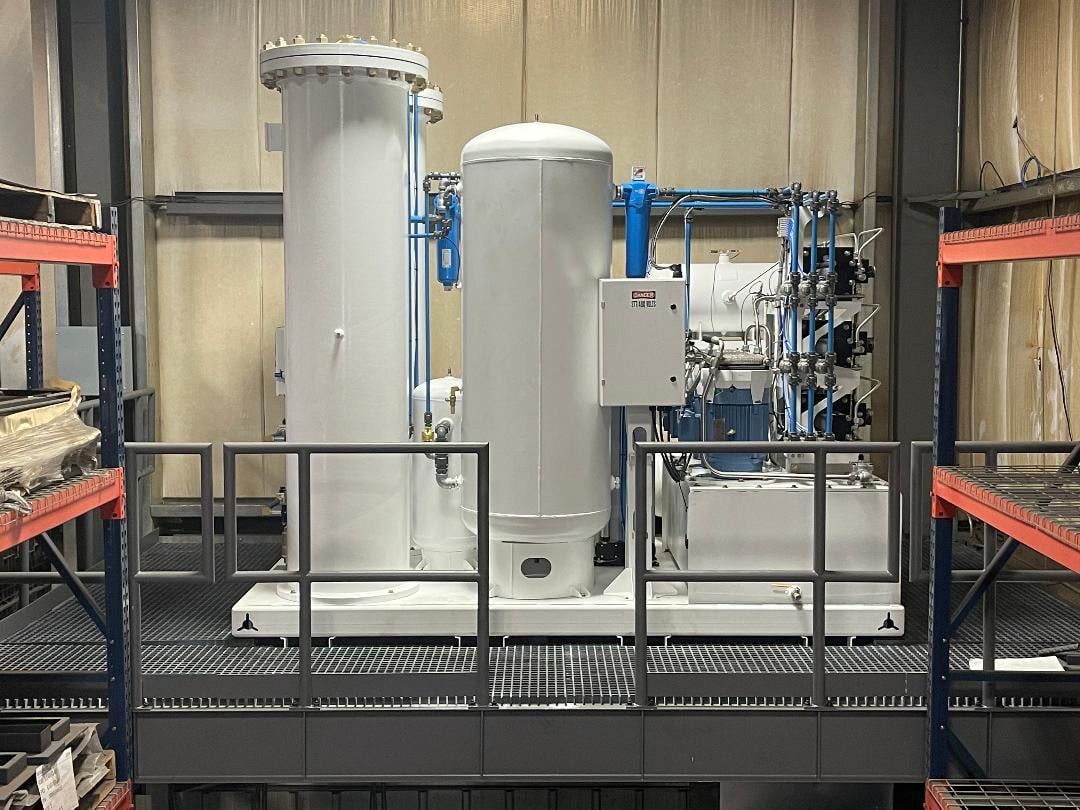

N2 Generator (99.999% purity) / Gas Mixing / Shop Air Cutting

Your partner in fabricated metal solutions

- Consistent Quality

- Increase Productivity

- Reduce Costs