Welding

November 23, 2023

Welding

Fabrication Expertise

We offer high-quality welding solutions tailored to meet the needs of various industries. We excel in manual GTAW (TIG), GMAW (MIG), resistance welding, robotic MIG, brazing, and flux-cored welding. Typical material types processed are carbon steel, stainless and aluminum. Whether high-volume production is required or low-volume solutions, we can meet your needs with precision and cost-effective results.

Our Welding Processes

Welding Technology

- Typical material thicknesses welded range from 22ga (.029") to 3.00" weighing up to 4,000 pounds

- 9,000 square feet dedicated to welding services

- 1,500 square feet available to accommodate large weldments with 2-ton & 1/2-ton overhead cranes

- (3) welding positioners that hold 900 pounds horizontally and 500 pounds in the vertical position

- Electrochemical weld cleaner machine that removes weld discoloration on stainless and aluminum

Robotic Welding

- Trumpf TruArc 1000 Robotic Welding Cell - Features include:

- Collaborative robot arm

- Two-station same side operation

- Component sizes up to 24" wide X 24" high X 78" long

- Rotary axis

Manual Welding

- (9) TIG machines

- (4) MIG machines

- (1) stud welding machine - Stud diameter welding range: M3 to M10 (#4 to 7/16")

Resistance Welding

- 200 kVA AC Projection welder with 18” throat depth

- 170 kVA DC Projection welder with 30” throat depth

- 100 kVA DC Rocker Arm welder with 24” throat depth

- 50 kVA AC Rocker Arm welder with 23” throat depth

- 50 kVA AC Rocker Arm welder with 23” throat depth

Welded Corner

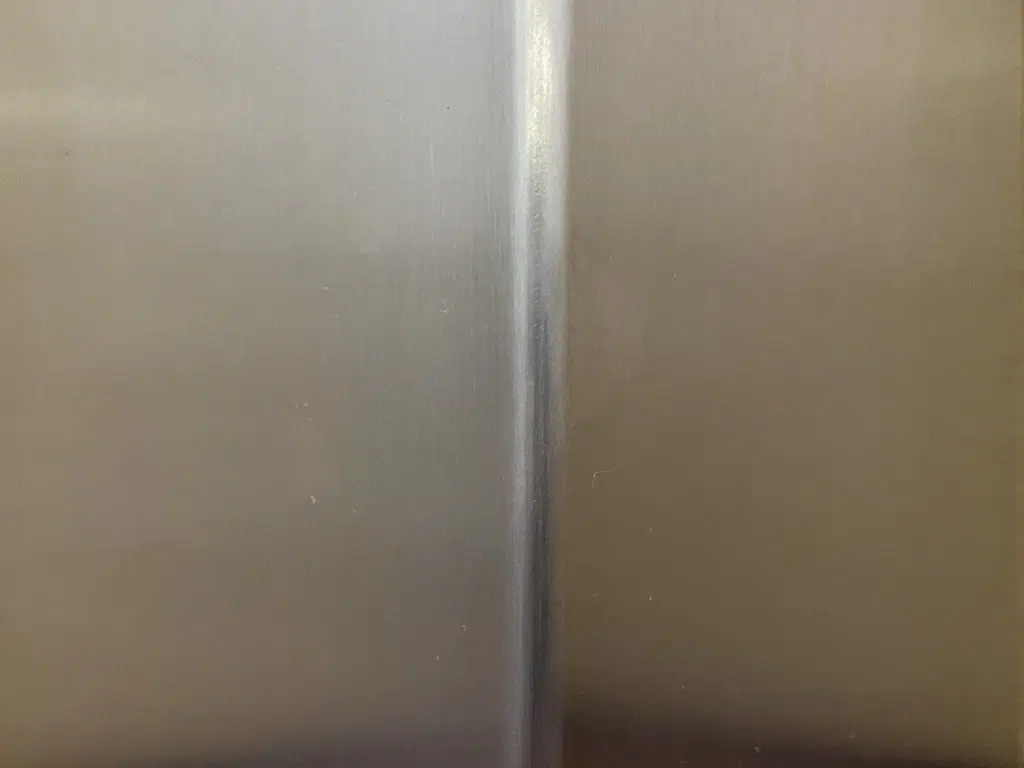

Rough Ground Corner

Blended Corner to a #4 Finish

Your partner in fabricated metal solutions

- Consistent Quality

- Increase Productivity

- Reduce Costs